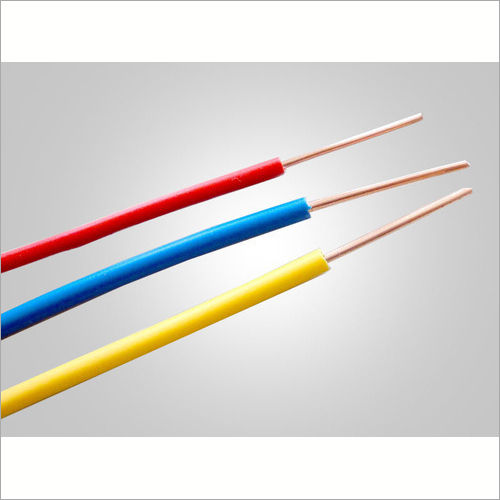

Electrical Insulated Wires

Product Details:

- Core Number 1, 2, 3, or as required

- Cable Type Single Core / Multi Core

- Conductor Shape Round

- Rated Temperature -10C to +80C

- Weight Varies as per size and length

- Dielectiric Strength Min 3.5 kV

- Conductor Type Solid/Stranded

- Click to view more

X

Electrical Insulated Wires Price And Quantity

- 500-1000 Kilograms

Electrical Insulated Wires Product Specifications

- High electrical insulation, flexible, durable, heat resistant, flame retardant

- Adequate for wiring (as per IS 694 standards)

- Red, Blue, Black, Green, Yellow and more

- Varies by size (e.g., 2.0 mm to 7.5 mm)

- PVC

- PVC insulated

- Indoor and outdoor

- Copper

- -10C to +80C

- Solid/Stranded

- Single core/Multiple core options available

- 90 meters

- -5C to +60C

- Electrical wiring in homes, offices, industries, panels

- Copper, PVC

- 0.5 sq.mm, 1 sq.mm, 1.5 sq.mm, 2.5 sq.mm, 4 sq.mm, 6 sq.mm

- Available in Red, Blue, Black, Green, Yellow, and more

- Copper

- Custom/As per requirement

- Up to 1100 V

- Min 3.5 kV

- Electrical Insulated Wires

- PVC (Polyvinyl Chloride)

- Internal wiring of appliances, industrial machines, control panels, building wiring

- 1, 2, 3, or as required

- Single Core / Multi Core

- Round

- Varies as per size and length

- -10C to +80C

Electrical Insulated Wires Trade Information

- As per demand Per Week

- 5-7 days Days

Product Description

Electrical Insulated Wires are found to be highly useful because this can be used for a variety of tasks in different industries. Further, it is extremely strong and durable due to its high capacity of bearing load and mechanical stress. This cable is made under the guidance of our professionals with the help of sophisticated technologies keeping in mind the set industrial norms. Our provided Electrical Insulated Wires are available in different sizes and lengths and praised for their unique features like flame resistant, flexible in quality and high tensile strength.

Engineered for Safety and Reliability

Our electrical insulated wires are crafted to meet the rigorous requirements of IS 694:1990, ensuring optimal safety and dependable performance under varying environments. The fire-retardant, PVC-insulated design works to minimize hazards, resist harsh chemicals, and protect against moisture ingress, making them ideal for diverse installations in homes, industries, and commercial spaces.

Versatility in Application and Customization

With options for single or multi-core, round solid or stranded copper conductors, and a variety of lengths, sizes, and color jackets, these wires fit a vast array of electrical setups. Their flexibility enables straightforward handling and installation, whether in control panels, internal appliance wiring, or general building applications, providing both efficiency and adaptability for every need.

FAQs of Electrical Insulated Wires:

Q: How are these electrical insulated wires safe for fire-prone environments?

A: These wires are designed with flame-retardant PVC insulation and adhere to IS 694:1990 standards, significantly reducing the risk of fire propagation. Their fire resistance ensures safer usage, especially in indoor building wiring and industrial installations.Q: What makes these wires suitable for use in industrial and home environments?

A: High electrical insulation, resistance to acids, oils, and moisture, and durability across a wide temperature range (-10C to +80C) make these wires versatile for multiple settings, including residential, commercial, and heavy-duty industrial applications.Q: When should I choose single core versus multi-core wires?

A: Single core wires are ideal for straightforward installations or when routing power to a specific point, while multi-core wires are preferred for complex panels, appliances, or machinery where multiple conductors are required within a single sheath.Q: Where can these insulated wires be installed?

A: These wires are suitable for both indoor and outdoor installations due to their robust insulation and resistance properties. Common uses include wiring in homes, offices, industrial machines, control panels, and appliances.Q: What is the process for determining the correct wire size for my project?

A: Wire size selection depends on the intended current load, as specified by IS 694:1990 standards. Choosing the appropriate cross-sectional area (e.g., 1.5 sq.mm, 2.5 sq.mm) ensures safe current carrying without overheating.Q: How does the PVC insulation benefit my electrical wiring installations?

A: PVC insulation delivers excellent dielectric strength (minimum 3.5 kV), flexibility for easy installation, and resistant properties against fire, chemicals, and moisture, leading to enhanced longevity and safety of your wiring systems.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email