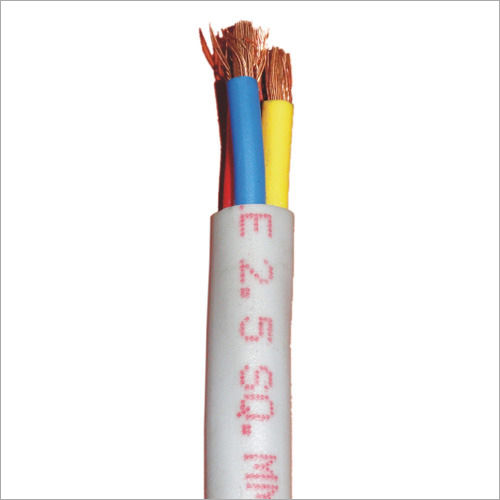

Flexible Multi Core Cable

Product Details:

- Diameter Varies with size and number of cores (e.g. 7 mm to 25 mm)

- Locking Type N/A (not applicable to bulk cable)

- Core Number 2 to 24

- Insulation PVC, ROHS compliant

- Operating Temperature -15C to +70C

- Install Type Fixed and mobile laying

- Weight Varies as per length and size

- Click to view more

Flexible Multi Core Cable Price And Quantity

- 100000 Metric Ton

- 10.00 - 3000.00 INR/Meter

- 2999 INR/Meter

- Indoor/Outdoor use

- Yes, meets IS 694 standards

- Optional

- Yes (available on request)

- Coil or Drum

- Smooth PVC outer sheath

- Yes

- Excellent resistance to abrasion, chemical, and weathering

- 7.5 x Overall Diameter

Flexible Multi Core Cable Product Specifications

- Black or Grey

- PVC, ROHS compliant

- Industrial machinery, control panels, power distribution, appliances

- Up to 1100 V

- As per cable configuration (e.g. diameter x length)

- Varies with size and number of cores (e.g. 7 mm to 25 mm)

- N/A (not applicable to bulk cable)

- 2 to 24

- Varies as per length and size

- Round

- Optional: Copper braid or Aluminum foil (based on specification)

- -15C to +70C

- Customizable (commonly available in 100 m rolls)

- Fixed and mobile laying

- Optional: Galvanized steel wire (on request)

- Flexible multi core

- Copper

- High flexibility, multi-core design, robust insulation, easy installation, suitable for dynamic applications

- PVC

- 2.5 kV for 1 minute

- Typically 60 - 80 Ohms (varies as per cable type)

- Flexible, multi-stranded

- Varies (typically not applicable for bulk cable)

- -15C to +70C

- -25C to +85C

- Control circuits, Power supply, Signal transmission, Indoor/Outdoor installation

- PVC (Polyvinyl Chloride)

- Copper conductor with PVC insulation and sheath

- Flexible Multi Core Cable

- 2 Core to 24 Core (as per order)

- Stranded Copper

- 0.5 sq. mm to 10 sq. mm (cross-section area)

- High, suitable for dynamic and static applications

- Indoor/Outdoor use

- Yes, meets IS 694 standards

- Optional

- Yes (available on request)

- Coil or Drum

- Smooth PVC outer sheath

- Yes

- Excellent resistance to abrasion, chemical, and weathering

- 7.5 x Overall Diameter

Flexible Multi Core Cable Trade Information

- Cash in Advance (CID)

- wooden packing

- All India

- BIS ISO

Product Description

Flexible Multi Core Cords are utilized in electronics, automotive and telecom sector for power transmission purpose. The inner cores are coded for ease of identification as per the national/international coding practices. Further, this core cords are made by using optimum grade PVC and copper wires under the direction of our expert professionals as per the set industrial norms. These cords are checked by our quality controllers with the help of most advanced instruments so that it does not lack on the performance criteria. Our offered Flexible Multi Core Cords are known for their unique features like fire proof finishing, flexible and light weight and resistant to shock.

Superior Flexibility for Demanding Applications

This multi core cable offers a unique blend of flexibility and strength, making it ideal for applications that require frequent movement, such as machinery, power distribution, and control panels. The stranded copper conductor ensures excellent current flow, while the robust insulation supports dynamic environments, reducing downtime and maintenance costs.

Enhanced Safety and Environmental Performance

Engineered to comply with IS 694 and ROHS standards, our cable delivers flame retardance, chemical resistance, and weatherproofing, promoting safe operation indoors and outdoors. Options for UV resistance, halogen-free construction, and steel wire armoring allow for adaptation to challenging environments and regulatory requirements.

FAQs of Flexible Multi Core Cable:

Q: How is the Flexible Multi Core Cable installed for both fixed and mobile applications?

A: The cable supports installation for both fixed and mobile laying. It can be routed through control panels or machinery, thanks to its high flexibility and minimum bending radius of 7.5 times the overall diameter, ensuring easy and secure placement without risk of damage.Q: What advantages does the flame retardant and oil resistant feature provide?

A: Flame retardant properties, as per IS 694, help prevent fire escalation, while oil resistance ensures longevity in environments exposed to lubricants and hydraulic fluids, making the cable safe and durable for industrial setups.Q: Where can this cable be utilized and what environments is it suited for?

A: This cable is ideal for indoor and outdoor environments, including industrial machinery, power distribution, appliances, and control circuits, due to its excellent resistance to abrasion, chemicals, and weathering.Q: When should I request optional features such as UV resistance, halogen-free, or armored versions?

A: Optional features should be requested when your application involves exposure to outdoor elements (UV), environments requiring halogen-free materials for reduced toxic emissions, or mechanical protection (armoring) against physical damage.Q: What is the process for customizing the cable in terms of length, core number, and color?

A: Custom orders can specify cable length, commonly in 100 m rolls or to specific project needs, choose between 2 to 24 cores, and select jacket color options including black, grey, or other shades as required.Q: How does the multi-core design benefit industrial applications?

A: Multi-core design enables consolidated control, power, or signal routing within a single cable, simplifying installation and maintenance while reducing space requirements and potential wiring errors.Q: What is the temperature and voltage rating for this cable?

A: The cable operates in temperatures ranging from -15C to +70C, with rated voltage up to 1100 V, accommodating a variety of power and control applications in diverse environmental conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+